December Adventure Day 16

An MNT-Flavored Palate Cleanser

After an increasingly frustrating few days bashing my head against Apple’s development environment, I decided it was time for a change of pace for day 16 of my Psion-themed December Adventure—it is meant to be a bit of low-stakes fun afer all.

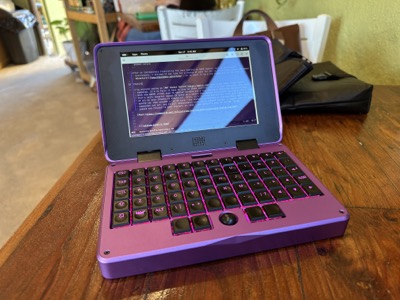

The incredibly extra MNT Pocket Reform

I’ve enjoyed owning an MNT Pocket Reform ever since their Crowd Supply campaign. It’s no Psion (I have to stay on theme somehow), but I’ve been incredibly impressed with how GNOME scales down to smaller screens and I love having a diminutive device on-hand that’s powerful enough to serve as a modern development environment with sufficient storage to have a copy of all my data (thanks Syncthing). Still, it’s far from perfect and feels a lot like a fussy sports car that demands frequent fettling—the keyboard controller is unpredictable, the WiFi cuts out, and it power cycles without notice.

I’ve long suspected many of these issues are related to poor thermals so, when I saw pandora’s post on the MNT forums describing the amazing improvements they’ve seen by replacing the FR-4-based PCB backplate with an aluminum panel, I knew I had to try it out for myself. Although they’ve published design files on their GitHub, it seemed like a good opportunity to try my hand at designing and ordering a custom CNC part.

Earlier this year, I ordered a prototype stand for StatusPanel from PCBWay (no, this post isn’t sponsored) that just happened to be purple anodized aluminum so I offered it up in place of the existing backplate to see how it felt and how well the color matched.

Much to my surprise, the color matched pretty closely—well enough to order a prototype. The contrasting darker purple might even prove a design feature.

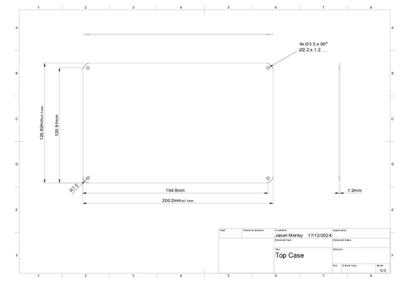

Encouraged by this, I set about figuring out the exact dimensions and tolerances of the backplate. Fortunately, MNT Research publishes all the schematics and designs for the Pocket Reform on GitHub, so I was able to use the backplate PCB designs for dimensions and the keyboard bezel technical drawings to get the CNC tolerances and details of the countersinks.

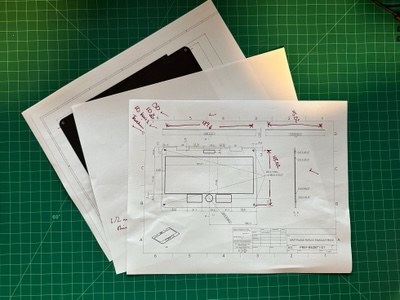

Sometimes it’s easier to work on paper

I had originally thought I would be able simply amend the keyboard bezel designs and use this for the backplate but when I sized it up (boy am I glad I did this), the screw holes didn’t line up:

Testing the keyboard bezel in place of the backplate

Much to my surprise, the vertical spacing of the screw holes on the top half of the case are different to the keyboard—the horizontal and vertical insets are very slightly different. I was able to confirm this by comparing the top PCB and keyboard bezel designs. Instead, I created my own designs from scratch, using a combination of dimensions from both:

With the design in place, I kicked off an order on PCBWay and now it’s just a matter of waiting; $70 shipped to Hawaii doesn’t seem at all bad for a custom milled and anodized part.

Having discovered such a significant mistake, I guess day 17 will involve a little more design work. That will also give me a chance to publish the design files so that others can use them (so long as everything works out in the end). I’ve reached out to PCBWay and let them know there’s an error in my design and hopefully they’ve not started production yet. 🤞🏻